Menu

Menu

Corrosions in Oil Field

Significant Obstacles Present in Oil Field

Fuel industry faces lot of issues and corrosion remains one of the negatively impacting issues in production. It disturbs the assurance points when it comes to processes involved in extraction and purification. In addition, this issue remains one of the restricting factors that control technical aspects also.

Resolving the Issues in Production

In view of supporting processing and production obstacles several researches have been made on applying suitable chemicals to eradicate formation of deterioration on components which get exposed to this issue with obvious possibilities.

Standards of Deterioration

The deterioration of products employed in extraction from fuel wells is a combination of many factors. Rust formation takes place mainly due to presence of hydrocarbons in the extracted material. Other things include impurities.

Role of Oxygen in Decaying

Oxygen also has an important role in oxidation of materials at the time of drilling. It contaminated the fluid at the time of drilling and corrodes the equipments involved in the process. Some of the products which get affected are casing of well, pipelines, mud handling equipment.

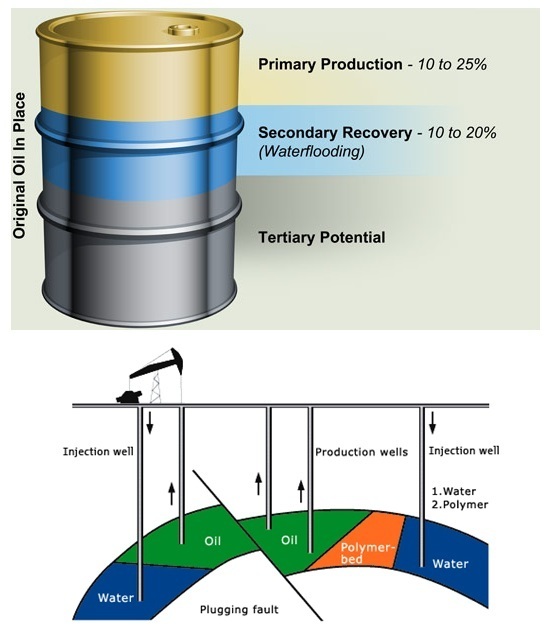

Reasons Affecting Petroleum Sector during Secondary Recovery

Acid is applied in many industries to reduce the impact of decompositions caused by water and carbon-di-oxide during second recovery. However, acid has a bad impact resulting in pipeline damages though it may help to remove scaling. It also affects metals in terms of erosion.

Other types of Corrosion Issues Caused by,

- Chemicals - Chemicals like Iron sulfide, hydrogen sulfide, etc when dissolved in water they reduce the pH level.

- Cavitations - It is otherwise called as loss of metal which happens due to high-pressure shock waves which are produced by collapse of high-velocity fluid bubbles when they cross metal surfaces. These can be found on pump impellers.

- Erosion - High-velocity abrasive particles will have direct impact on the metal surfaces therein metal components like drill pipes become weaker.

Preventive Measurements

Fuel industry considers these issues to be the most challenging ones for which acid corrosion inhibitors remain the best solution to protect metal parts and pipe lines from corrosive environment.

Role of Inhibitors In Reducing Decay of Metal Parts

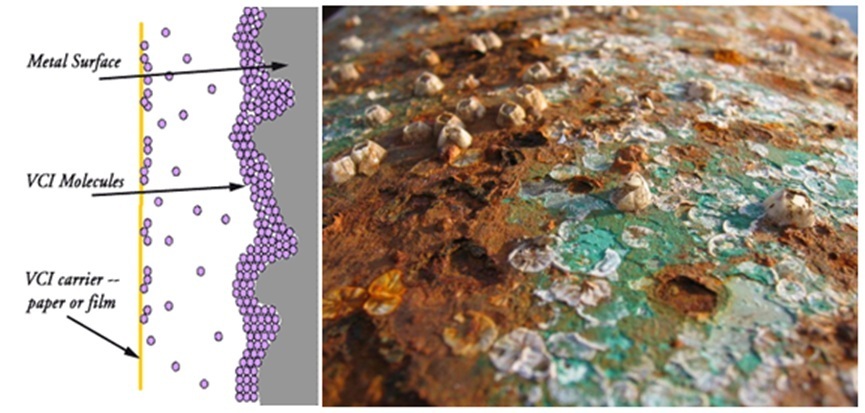

Defects caused by CO2 and H2S are similar for which pH must be raised so the acid effects on the devices will get reduced and in this procedure coating drill pipelines with anticatalysts.

How it helps?

The essentiality of using anticatalyst is felt at the time of increasing pH level and acid impact. These form into protective film like layers over the components and prevent rusting or scaling to a great extent. In addition, there are different types of this chemical which are selected for application based on its strength to react with impurities and acid.

Different Forms of Inhibitors

Depending on the requirement of solubility and dispersion there are three main groups of anticatalyst produced such as oil-soluble, water and oil soluble and water dispersible.

Manufactures of Oil Field Chemicals

Rimpro-India is one of the well-established companies that produce top range of oilfield chemicals and other chemicals to support the fuel industry.

Conclusion

Drill pipes used in oil wells are exposed to different kinds of corroding factors. These can be prevented by using suitable inhibitors.

This article has been written by Govind Patel.