In the oil industry water and crude oil come into contact on many occasions, forming emulsions stabilized by various components in the oil, such as asphaltenes and resins. These emulsions are thermodynamically stable but kinetically unstable, lasting forever or for a long time, and they can be separated by chemical treatment.

The main factors that influence the emulsion separation efficiency are the type of emulsifying agents and the amount of water in the emulsion.

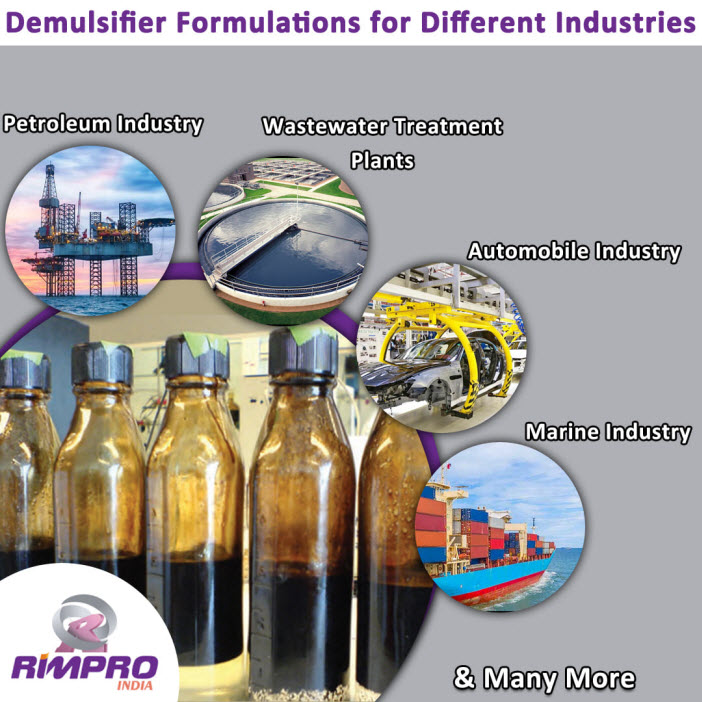

Demulsification is a fascinating scientific process that plays a crucial role in various industries such as oil and gas, wastewater treatment, and food processing.

What is Demulsification?

Demulsification is the process of breaking down emulsions, which are mixtures of two or more immiscible liquids, typically oil and water, stabilized by surfactants. Emulsions are commonly encountered in industrial processes and natural environments. Demulsification aims to separate these emulsions into their individual components for further processing or disposal.

Why is Demulsification Important?

Demulsification is crucial for several reasons. Firstly, in the oil and gas industry, crude oil is often found in the form of water-in-oil emulsions. These emulsions can impede the separation of water and oil, making it challenging to refine and extract valuable hydrocarbons. Efficient demulsification processes allow for enhanced oil recovery and improved oil quality.

Secondly, in wastewater treatment, demulsification is essential for separating oil and grease from water. Emulsions in wastewater can hinder the treatment process and cause environmental pollution if not properly addressed. Demulsification techniques ensure effective separation and enable the recovery of valuable resources.

How Does Demulsification Work?

Demulsification involves disrupting the surfactant film that stabilizes the emulsion, leading to the coalescence or separation of the immiscible liquids. The process typically consists of the following steps:

Destabilization: Demulsification begins by destabilizing the emulsion. This can be achieved through various mechanisms, including the addition of demulsifiers, changes in temperature, or applying mechanical shear forces.

Coalescence: Once the emulsion is destabilized, the dispersed droplets begin to coalesce, forming larger droplets. Coalescence can be facilitated by gravity, centrifugal forces, or the use of coalescing agents.

Separation: The coalesced droplets eventually separate from the continuous phase of the emulsion. The separation can be achieved through gravity settling, flotation, or filtration, depending on the specific demulsification technique employed.

Factors Affecting Demulsification

Several factors influence the efficiency of demulsification:

Emulsion Composition: The composition of the emulsion, including the type of oil, surfactants, and water content, affects demulsification. Different demulsifiers may be required for specific emulsion compositions.

Temperature: Demulsification can be temperature-dependent. Changes in temperature can alter the stability of the emulsion and the effectiveness of demulsification techniques.

pH: The pH of the emulsion can influence demulsification. Adjusting the pH can help optimize the process and improve separation efficiency.

Common Demulsification Techniques

Chemical Demulsifiers: Chemical demulsifiers are additives specifically designed to destabilize emulsions. These demulsifiers work by disrupting the surfactant film, reducing interfacial tension, and promoting coalescence. They are widely used in the oil and gas industry and come in different types, such as oil-soluble and water-soluble demulsifiers.

Mechanical Demulsification: Mechanical demulsification involves the application of shear forces to break down emulsions. This can be achieved through various equipment and processes, such as centrifugal separators, hydro cyclones, or high-speed mixers. Mechanical demulsification is commonly employed in wastewater treatment and food processing industries.

Electrostatic Demulsification: Electrostatic demulsification utilizes electrical fields to enhance the separation of emulsions. By applying an electric field, the charged droplets in the emulsion experience attractive or repulsive forces, leading to coalescence and separation. Electrostatic demulsification is effective in treating water-in-oil emulsions.